Electric Resistance Hot Dip Galvanizing Furnace Same Western Technology

Electric Resistance Hot Dip Galvanizing Furnace Same Western Technology

Electric Resistance Hot Dip Galvanizing Furnace Same Western Technology

We are professional manufacturer galvanizing furnace,galvanizing furnace with PLC automatic intelligent control, high combustion efficiency, a mature technology. Heating medium natural gas, liquefied petroleum gas, electricity, coal, coal gas and so on! Auto PLC control heat-up system electrically ,gas,oil heated

| Galvanizing kettle Size | Customer offer or we design as customer need |

| Power | Design according the capacity and kettle size |

| Capacity | Design according to customer requirements |

| Work time | Normal 10hours/day;20hours/day;300 days/year |

All core components are imported from the world's top brands!

| Heat system | Kanthal Resistance Strip Sweden |

| Electronic control | Siemens,or Shimaden Japan |

| Insuation module | Morgan or Isolite Japan |

Design advantages:

With the advanced design concept of the United States, the overall performance of the furnace has reached the international leading level!

Sufficient power density is reserved in the design, which can ensure the rapid temperature rise of the system in an instant, so that the hot-dip galvanizing plant can produce continuously, save time, and improve production capacity.

Low energy consumption and environmental protection, precise temperature control, up and down not more than ± 1-2 ℃, the sheath is high temperature resistant and resistant to zinc corrosion heat.

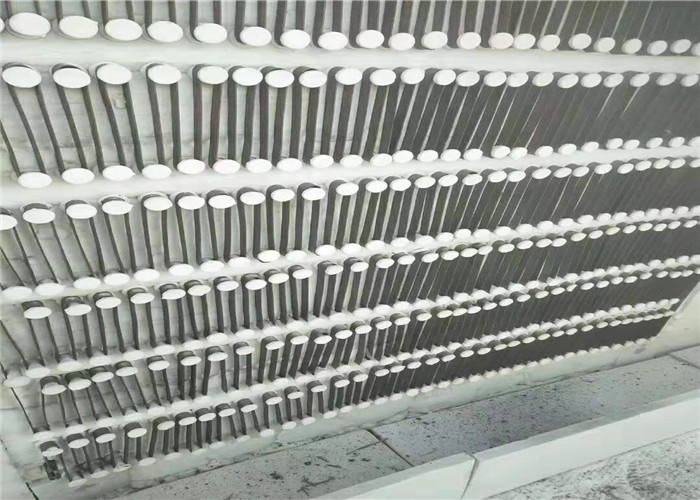

The resistance belt adopts the world's top brand of Kanthal Sweden, with long service life and stable heating, which ensures the stable performance of the galvanizing furnace, saves maintenance time and reduces the downtime.

The structure design of galvanizing furnace is simple, and the installation is easy. Customers only need to build concrete base according to the tunnel drawing of galvanizing furnace provided by our company, so as to save the cost of infrastructure construction.

The unique U-shaped support design is used to support the galvanizing furnace and the galvanizing kettles.

Advantages:

Structure part: it adopts the whole refractory fiber furnace structure, which has excellent heat insulation performance; the electric heating furnace adopts the door type resistance heating plate which can be easily removed for heating; it adopts the technology of directly hanging electric heating wire (belt) to improve the radiation coefficient of the electric heating element, with high thermal efficiency, long service life of the electric heating element, convenient installation and maintenance.

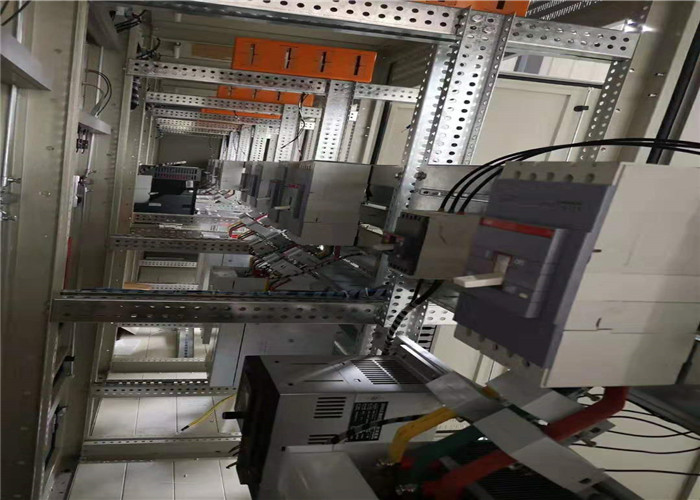

Electrical part:

a. The main control components are imported high-quality components, with the characteristics of safety, stability and low failure rate.

b. Good grounding design, with conventional short-circuit, overload, leakage and other protection measures, adopt the principle of separate wiring of strong current and weak current to design and assemble the electric control cabinet.

c. With start, stop, emergency stop, alarm reset control, and with current, voltage, operation, stop, control power, power output indication and other functions.

Control part: automatic control mode: the control mode adopts stepless power regulation to avoid power output gap. The intelligent temperature control instrument or PLC is used to control the on-off ratio of SSR, so as to avoid the high-order harmonic pollution to the power grid caused by SCR voltage regulation.

Temperature detection: use high-precision thermocouple to detect each heater and zinc liquid, feed the detected temperature signal back to PLC, and compare with the set temperature. PLC has PID fuzzy control and self-tuning adjustment function to adjust the output power of heater, and realize the automatic temperature control of heater. At the same time, the temperature of each heating plate shall be monitored in real time. If there is over temperature, the heating plate shall be stopped at any time to ensure the safety of the heating plate.

It can provide signal interface to the user's DCS system, and control the start and stop of the heater through the user's DCS system; it can indicate the operation, stop and alarm interlock status of the heater, and it can also indicate the temperature of the heater and realize remote temperature control through the DCS control system.

Our furnaces service life is the same as Western Technologies standard, Greatly save customers' production costs!We have higher cost performance!

If that product interest you, please contact us.!